Geotechnical

Engineering

Soil, rock, and groundwater conditions at every site are different. We assess the specific site conditions and design earth structures (slopes, channels, and dikes), foundations (retaining walls, bridges, buildings, tanks), and subsurface structures (clarifiers, lift stations, buried utilities, tunnels) to economically achieve the specific project objectives.

Learn More →

Construction Materials

Engineering

& Testing

Construction material performance is key to the function and durability of any project. We engineer and test materials such as soil, concrete, and asphalt so you get what you pay for and the project performs as expected.

Learn More →

Civil/Pavement

Engineering

A successful project starts with clear understanding of the project’s specific needs. We prepared street rehabilitation PS&E, traffic control designs, pavement designs, and asset management systems based on careful understanding of design requirements.

Learn More →

Environmental Geology

& Engineering

Impact from hazardous waste, wetlands, faulting, and/or NEPA processes are serious concerns for project development. We identify such concerns early in project development, and provide strategies to mitigate impacts and provide the proper regulatory approval so the project can proceed on time and achieve the project goals.

Learn More →

Roads & Bridges

Congestion and failing road surfaces cause delays, vehicle damage, and even driver safety issues. Solving these problems requires our specialized knowledge of pavement and roadway structures.

Learn More →

Water, Wastewater & Flood Control

Drinking water, flushing toilets, and dry streets for granted – until they are gone. We specialize in keeping these systems running effectively.

Learn More →

Airports, Ports & Dredging

Expanding and maintaining ports and airports is crucial to our economic development. HVJ’s specialized pavement, wharf, and navigation channel experience makes it happen.

Learn More →

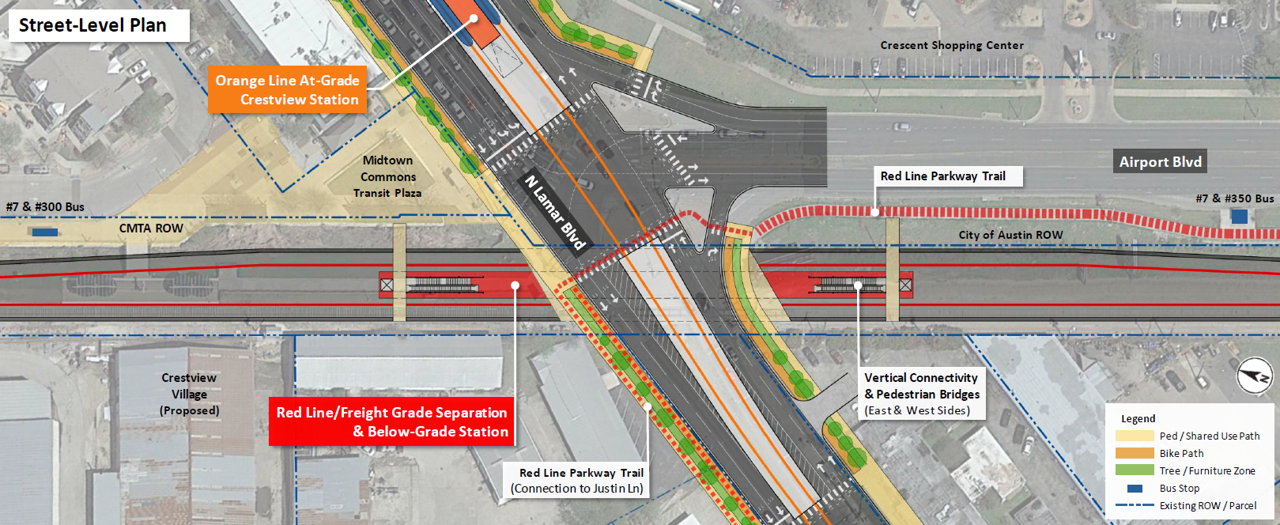

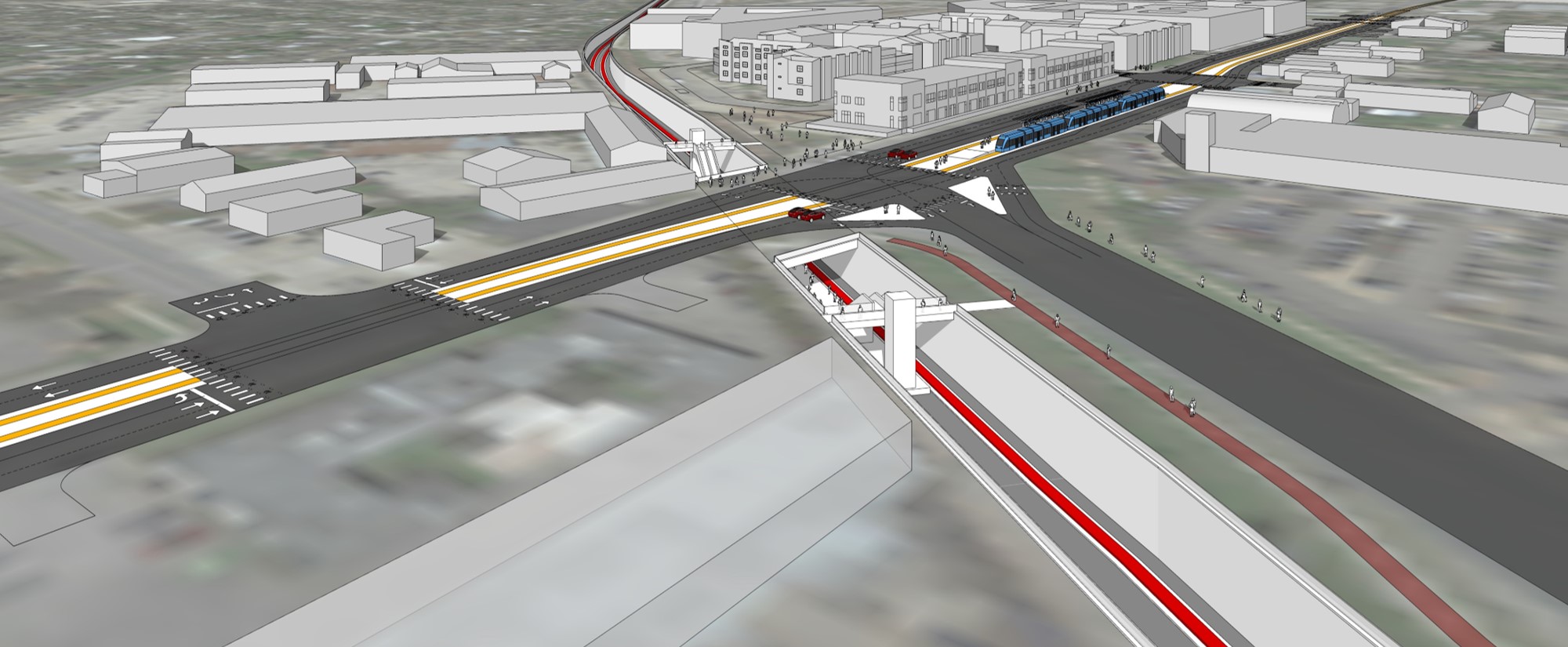

Rail & Transit

Rail and public transit facilities enable efficient transportation of people and goods. Our detailed knowledge of AREMA requirements keeps projects on track.

Learn More →

Buildings & Parks

Schools, universities, courts, parks, solid waste facilities are all critical to our society. HVJ has specialized knowledge and experience with a multitude of public projects.

Learn More →

HVJ Difference

Our engineers provide a unique blend of capabilities and experience because of the support they receive. Employees do not simply exist here. They thrive.

Learn More →

Culture

We are committed learners, empowered to interact based on making strong commitments. We take ownership of our actions and results.

Learn More →

Benefits

We believe in taking care of our employees. We offer a rewarding work experience, opportunities for advancement and competitive benefits.

Learn More →

Employee Stories

Check out what our employees say and learn about the HVJ experience! Great people and even greater teams are behind every project.

Learn More →

Current Openings

We're always looking for talented individuals who fit our culture and can bring new perspectives and experiences to our growing teams.

Learn More →

The Opportunity

Own a successful engineering business by adding our proven systems to your engineering talent and network.

Learn More →

How It Works

Help us branchise – you help us build a branch office and then convert it into your own franchise.

Learn More →

Who's A Fit?

Are you energetic and confident? See if this might be an opportunity that fits you.

Learn More →

Success Stories

Hear about the outstanding results our current franchisees have produced using our proven systems.

Learn More →

Geotechnical

Engineering

Soil, rock, and groundwater conditions at every site are different. We assess the specific site conditions and design earth structures (slopes, channels, and dikes), foundations (retaining walls, bridges, buildings, tanks), and subsurface structures (clarifiers, lift stations, buried utilities, tunnels) to economically achieve the specific project objectives.

Learn More →

Construction Materials

Engineering

& Testing

Construction material performance is key to the function and durability of any project. We engineer and test materials such as soil, concrete, and asphalt so you get what you pay for and the project performs as expected.

Learn More →

Civil/Pavement

Engineering

A successful project starts with clear understanding of the project’s specific needs. We prepared street rehabilitation PS&E, traffic control designs, pavement designs, and asset management systems based on careful understanding of design requirements.

Learn More →

Environmental Geology

& Engineering

Impact from hazardous waste, wetlands, faulting, and/or NEPA processes are serious concerns for project development. We identify such concerns early in project development, and provide strategies to mitigate impacts and provide the proper regulatory approval so the project can proceed on time and achieve the project goals.

Learn More →

Roads & Bridges

Congestion and failing road surfaces cause delays, vehicle damage, and even driver safety issues. Solving these problems requires our specialized knowledge of pavement and roadway structures.

Learn More →

Water, Wastewater & Flood Control

Drinking water, flushing toilets, and dry streets for granted – until they are gone. We specialize in keeping these systems running effectively.

Learn More →

Airports, Ports & Dredging

Expanding and maintaining ports and airports is crucial to our economic development. HVJ’s specialized pavement, wharf, and navigation channel experience makes it happen.

Learn More →

Rail & Transit

Rail and public transit facilities enable efficient transportation of people and goods. Our detailed knowledge of AREMA requirements keeps projects on track.

Learn More →

Buildings & Parks

Schools, universities, courts, parks, solid waste facilities are all critical to our society. HVJ has specialized knowledge and experience with a multitude of public projects.

Learn More →

HVJ Difference

Our engineers provide a unique blend of capabilities and experience because of the support they receive. Employees do not simply exist here. They thrive.

Learn More →

Culture

We are committed learners, empowered to interact based on making strong commitments. We take ownership of our actions and results.

Learn More →

Benefits

We believe in taking care of our employees. We offer a rewarding work experience, opportunities for advancement and competitive benefits.

Learn More →

Employee Stories

Check out what our employees say and learn about the HVJ experience! Great people and even greater teams are behind every project.

Learn More →

Current Openings

We're always looking for talented individuals who fit our culture and can bring new perspectives and experiences to our growing teams.

Learn More →

Agencies

HVJ has been proud to support hundreds of public agencies meet and exceed service expectations from their constituents.

Learn More →

Consultant Clients

We’ve developed ongoing teaming relationships with many consulting firms based on delivering outstanding client satisfaction.

Learn More →

HVJ Difference

Our engineers provide a unique blend of capabilities and experience because of the support they receive. Employees do not simply exist here. They thrive.

Learn More →

Culture

We are committed learners, empowered to interact based on making strong commitments. We take ownership of our actions and results.

Learn More →

Benefits

We believe in taking care of our employees. We offer a rewarding work experience, opportunities for advancement and competitive benefits.

Learn More →

Employee Stories

Check out what our employees say and learn about the HVJ experience! Great people and even greater teams are behind every project.

Learn More →

Current Openings

We're always looking for talented individuals who fit our culture and can bring new perspectives and experiences to our growing teams.

Learn More →

The Opportunity

Own a successful engineering business by adding our proven systems to your engineering talent and network.

Learn More →

How It Works

Help us branchise – you help us build a branch office and then convert it into your own franchise.

Learn More →

Who's A Fit?

Are you energetic and confident? See if this might be an opportunity that fits you.

Learn More →

Success Stories

Hear about the outstanding results our current franchisees have produced using our proven systems.

Learn More →